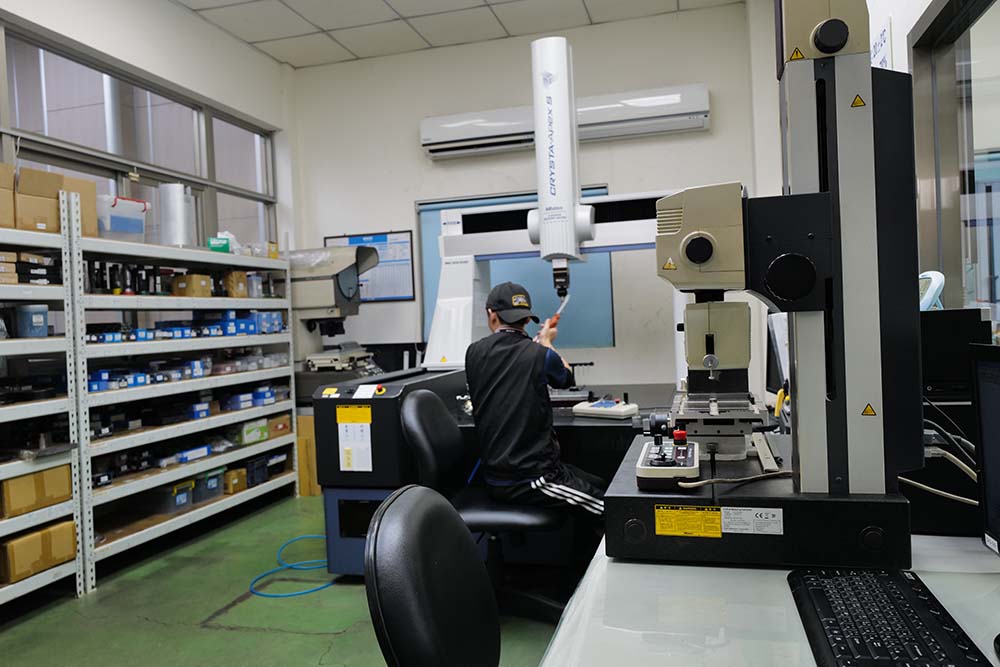

Precision Inspection

Ho Song owns multiple high-precision Coordinate Measuring Machines (CMM) from Japan and Germany, capable of measuring dimensions with extreme accuracy up to 2 meters. All measuring equipment undergoes regular internal and external calibration according to international standards, ensuring high accuracy and reliability of measurement results while supporting precise measurements of complex workpieces. The accuracy of such equipment not only improves measurement data precision but also enhances traceability in the manufacturing process.

Automated Data Transmission Inspection Equipment

For critical dimensions of specific customers, Ho Song is equipped with advanced Bluetooth-connected automated inspection equipment, including digital calipers. This equipment can automatically transmit measurement data in real time to the backend Statistical Process Control (SPC) system, enabling real-time data processing and analysis to enhance accuracy and responsiveness, ensuring continuous quality monitoring during production. The real-time data feedback of this system helps quickly detect and resolve any abnormalities in the production process, significantly improving production efficiency and quality stability.

Quality System Management

Ho Song's quality management system includes advanced quality control methods such as Control Plan, Failure Mode and Effects Analysis (FMEA), Measurement System Analysis (MSA), and Production Part Approval Process (PPAP). Comprehensive quality control is implemented at every stage, from design and manufacturing to shipment, ensuring product stability and consistency throughout its lifecycle. These systems not only ensure excellent product quality but also provide a foundation for continuous improvement, driving higher quality standards in every project.

Corrosion Resistance Testing

We have specialized salt spray testing equipment and collaborate regularly with metal analysis centers for instrument calibration and performance verification, ensuring the accuracy and reliability of test data. This testing effectively evaluates product corrosion resistance in extreme environments and ensures long-term reliability. Such testing enables us to provide customers with products that maintain excellent performance in various environmental conditions, strengthening customer confidence.

Functionality Testing

To fully meet customer requirements, Ho Song provides a range of functional tests, including durability testing and load testing. These tests verify the long-term operational performance and reliability of products under various real-world conditions, ensuring that every product operates effectively under the most demanding conditions. These tests not only ensure product functionality but also guarantee efficient operation in practical applications.

Gas Leak Testing

Ho Song provides high-pressure water tightness testing and high-precision air tightness testing equipment, comprehensively testing whether the product has any pores or leakage. Through these efficient testing methods, we ensure the air tightness and safety of all products, meeting the strict air tightness standards of various industries. Precise air tightness testing not only guarantees the safety of the product during use but also avoids potential risks caused by leakage, ensuring the quality and reliability of the product.